100kg/h Waste PP Woven Bag Pelletizer Machine Line For Recycling

It is suitable for regeneration and granulation of waste plastics,

as HDPE, LDPE, and PP, EVA, BOPP etc.

It is equipped with quick motor-operated filter-screen-replacing

unit and automatic temperature control.

The 100kg/h Waste PP Wooven Bag Pelletizer Machine Line For

Recycling uses adjustable speed motor , ABB inverter for lower

power consumption , Omron precise temperature conroller ,siemens

contacter , piloting with an extruding machine at the same

discharging speed synchronistical. The unit is easy to operate,

With a high output, steady performance,lower consumption and

favorable economic benefit, long uselife , 1 year warranty time ,

24 hours service after sale

Applicable plastic materials: PE, HDP E, LDPE, PP, BOPP, etc

Material shapes: Film, bag, (PE, PP) regrind

Material types: Rolls, loose, bundled

Material comes from offcut, industry defective film, washed film

and printed film.

Note: Depending on different material properties, various

downstream equipments are needed.

1. High efficiency

Compared with the primary design, the output of PURUI second

generation film granulator machine has been increased 20%.

2. Low power consumption

The power consumption reduced 15% compared with the primary

design,.

3. Highly automatically,

Only 2 people for one production line.

Processing :

Worker put film or bag into Agglomerator---------plastic

ball---------screw loader feeds plastic into extruder

hopper----------extruder plasticizing process( vent screw

)---------Hydraulic network(for impurity sorting)-----

----Mold ( for 3mm diameter pellet ) ---------water bath

cooling--------forcecoolingfan ( for cooling and

water blowing )---------pelletizer (could adjust pellet length by

adjusting cutting speed )---------Vibrating Screen ( for sorting

good quality and size pellet )

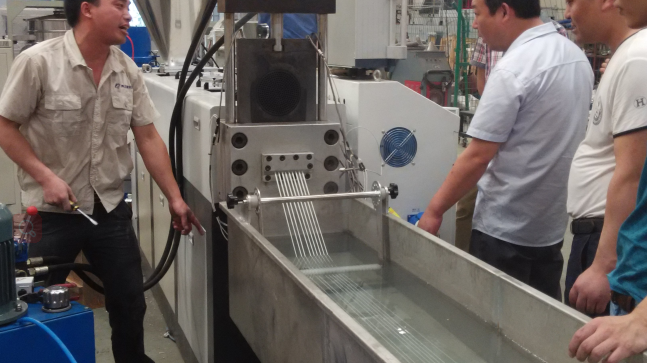

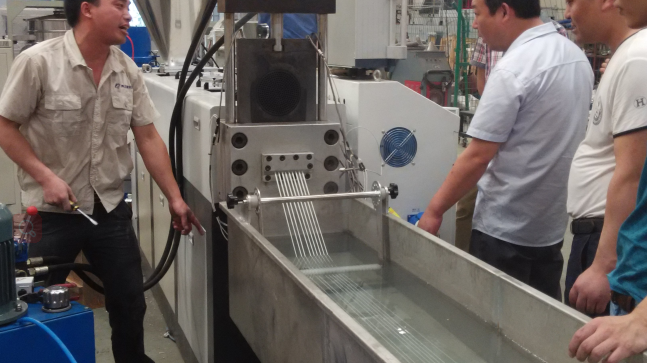

Machine Chart:

| NO. | Machine Name |

| 1. | Plastic Agglomerator |

| 2. | Screw Loader |

| 3. | Single Screw Extruder |

| 4. | Hydraulic network |

| 5. | Mold |

| 6. | Water Cooling Bath |

| 7. | Force Cooling Fan |

| 8. | Pelletizer |

| 9. | Vibrating Screen |

| Voltage | 3 phase 380V 50HZ or optional |

Detailes :

| 1. GXL-100 Plastic Agglomerator |

| Volume: 100L |

| Effective volume: 75L |

| Capacity: 100kg/h |

| Driving motor power: 37kw |

| Rotating speed: 1050rmp/min |

| Rotating blade: 2pcs |

| Fixed blade : 6pcs |

| Blade making material: 9CrSi steel |

| Discharge type: pneumatic |

| Cooling type: water cooling |

|

| 2. Screw Loader |

| Capacity: 150kg/h |

| Feeding screw diameter :80mm |

| Screw making material : high quality steel |

| Hopper making material :304 stainless steel |

| Driving motor power:1.5kw AC |

| Motor brand: china brand with CE |

|

| 3. SJ75 single screw extruder |

| Screw diameter :75mm |

| L/D: 30:1 |

| Capacity: 100kg/h |

| Screw type: vented screw |

| Screw and Barrel making material: 38CrMoAlA |

| Hardness of Screw : HV900-1000 |

| Depth of Nitrogen Treatment: 0.4-0.7 mm |

| Screw Straightness: <0.015 mm |

| Main Motor Power : 37kw |

| Barrel heater type : Cast aluminum heater |

| Heating temperature range: 0-380℃ |

| Heating zones: 12kw |

| Barrel cooling type: forced air cooling |

| Water cooling jacket for barrel cooling: Yes |

| Fan power: 0.48kw |

| Screw Max Rotating Speed: :0-89rmp |

| Center height: 1000mm |

| Weight: 1200kg |

| Control system : |

| ABB brand inverter (speed control) |

| Omron brand temperature controller ( temperature control ) |

| Siemens brand contactor |

| Parts: |

| Screw and Barrel brand: zhoushan brand |

Gearbox brand : jiangyin brand , Gear type: hard tooth -faced speed reducer |

| Motor brand: xindali brand ( CE marked ) |

|

| 4. Hydraulic network |

| Making material: high quality steel |

| Matched with heating rod : yes |

| Net hole size : optional |

| Net changer type: hydraulic pressure driving |

| hydraulic pressure station driving motor: 3kw |

| Motor brand: china brand with CE |

| Pressure meter matched : yes |

| Pressure senseor matched : yes |

|

| 5. Mold |

| Mold and head material : 40Cr steel |

| High quality tooling steel |

| Mold hardness: HV950-1050 |

| Final pet strand hole size : 3mm diameter or Could be customized |

| Heating band matched : yes |

|

| 6. water cooling bath |

| Working performance: final strand cooling |

| Main making material : 304 stainless steel |

| Tank length: 4M |

| Machine structure: Q235 steel |

| Matched with nylon material traction rollers *4pcs |

| Including water valves |

| Center height 1000mm |

| Tank height adjustment : +-90mm |

|

| 7. Force Cooling Fan |

| Heating dryer driving motor: 3kw |

| Drying pipe making material: 304 stainless steel |

| Traction roller making material: 4pcs*nylon material |

| Water collection device for reuse: yes |

|

| 8. Pelletizer |

| Granule cutting machine power: 1.1kw |

| Motor brand: china brand with CE |

| Cutting Speed : 125-300r/min |

| Traction type: rubber roller traction |

| Traction roller clamp type : manual screw press |

| Cutting blade making material: 9Crsi steel material |

| Blade; 1 pcs fixed blade ,1 pcs rotating blade |

| Cutting speed control : ABB inverter control |

| Center height: 1000mm |

|

| 9. Vibrating Screen |

| Driving motor power: 0.55kw*2 |

| Screen size could be designed. |

| All parts touched with granule is made by high quality stainless

steel |

| Driving motor power: 0.55kw*2 |

| Screen size could be designed. |

| All parts touched with granule is made by high quality stainless

steel |

| Driving motor power: 0.55kw*2 |